GRP or glass reinforced plastic, also known as fiberglass, is an innovative and durable material that has been used both for domestic and industrial construction applications for decades.

This material possesses an exceptional strength and weight-bearing capacity, which makes it perfect for use in aerospace, marine, automotive, and urban development industries.

There are many benefits of GRP over traditional metal or concrete-based construction materials, including low cost, low maintenance, electrical insulation, and longer life, to name just a few.

But what exactly is GRP made up of? And how can different industries benefit from it? These are some questions that this blog will try to answer. So, stay with us till the end to know everything there is about the components, uses, and benefits of GRP.

- What is GRP?

- Key Components of GRP

- Benefits of GRP

- Uses of GRP

What is GRP?

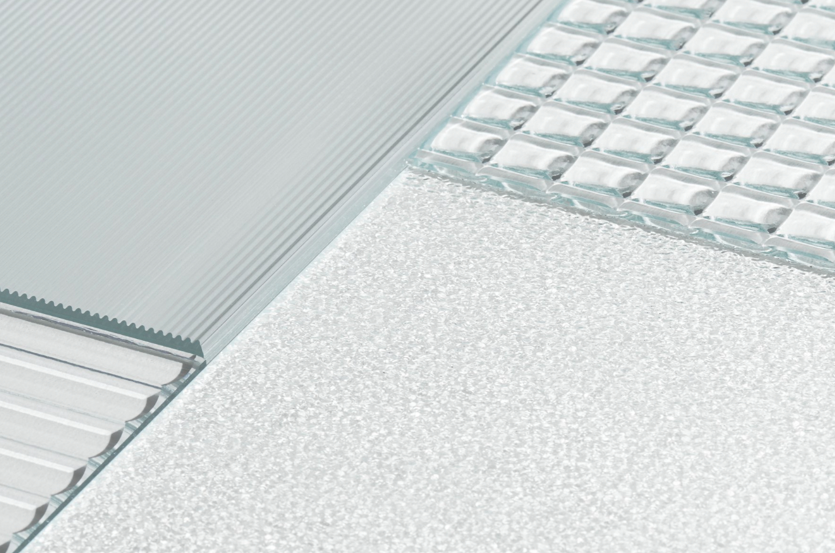

GRP is basically a composite material that is made by combining two different substances, i.e., glass fibers and polymer resin matrix, to create a material with enhanced physical and functional properties. This material is recognized globally for its exceptional strength, flexibility, and lightweight construct.

By combining the strength of glass fibers with the versatility of plastic resins, this material gives you unparalleled aesthetics with additional features like thermal conductivity, UV-resistance, impact resistance, and design flexibility.

The glass fibers do very well under tensile forces, while plastic resins can bear high compressive loads. In GRP, both of these properties are combined and enhanced, which makes it useful for plenty of industrial applications where the material has to bear heavy loads or foot traffic.

Key Components of GRP

The following are some key GRP components that contribute to its exceptional features.

1. Glass Fibers

The main purpose of glass fibers is to provide reinforcement or structural support to GRP. These fibers or fine strands are either woven, chopped, or matted to add tensile strength to the composite. These fibers act just like concrete rebars that provide strength and resistance to stretching under stress.

For advanced applications, Aramid or Carbon fibers are used to impart extra strength to GRP components such as GRP walls or GRP manhole covers.

These fibers are used in the following forms in GRP.

- Chopped strand mat (CSM)

In this case, the fibers are oriented randomly to give you multidirectional strength.

- Continuous filaments

These are long fibers that provide extra tensile strength.

- Woven roving

These are interlaced glass fibers that give you greater strength in specific directions based on your applications.

2. Polymer Resin Matrix

The polymer resin acts as a matrix or binder that binds glass fibers together and facilitates the stress distribution or transfer between them. The shape and surface finish of the GRP material also rely on the type of resin matrix that you choose.

The choice of resin also affects how the GRP will behave in terms of its chemical, weather, and heat resistance.

The following are some common polymer resin matrixes used in GRP.

Epoxy Resin: These are used in high-performance applications where you require very high bonding and mechanical strength.

Polyester Resins: These cost-effective resins are used in general or low-performance applications.

Vinyl Ester Resins: These are perfect for corrosive environments due to their exceptional chemical and moisture resistance.

3. Additives or Fillers

Some GRP materials contain additives or fillers that can either enhance their performance or customize their strength and durability based on your specific needs. The use of additives or fillers can also lower the production cost of GRP.

Some common examples include.

- Pigments or dyes to color the final GRP products.

- Silica or calcium carbonate to customize mechanical properties.

- Fire Retardants to make the GRP fireproof.

- UV Stabilizers to prevent damage from constant sunlight exposure.

4. Catalysts and Hardeners

These are also an important but less talked-about component of GRP. The job of hardeners or catalysts is to initiate the curing of the resins, which turns them from a liquid to a solid state. These catalysts trigger a chemical process that solidifies the resins and bonds them permanently with the glass fibers.

These are in the form of:

- Amine-based hardeners that are used in epoxy-based resins.

- MEKP (Methyl Ethyl Ketone Peroxide) that are used in polyester resins.

Each component of the GRP imparts specific features to the final material. By altering the type or ratio of glass fibers, resins, additives, or hardeners, you can create GRP products like structural elements, piping, building facades, or GRP manhole chambers that are tailored to specific applications.

Benefits of GRP

GRP is far superior to traditional construction materials in terms of its strength, versatility, and aesthetics. The following are some additional benefits of opting for this material in your residential and commercial projects.

- It has a higher strength-to-weight ratio, which makes it very durable but easy to handle.

- GRP is a polymer and glass-based material, which gives it higher corrosion and moisture resistance.

- GRP gives you flexibility in terms of its design, color scheme, textures, and functionality.

- This material gives you a much longer service life with very little maintenance.

- GRP gives you excellent UV resistance, which makes it perfect for outdoor use.

- GRP products are prefabricated and lightweight, which makes their installation and maintenance easier and risk-free.

- GRP is a nonconductive material, which makes it perfect for creating electrical enclosures, manhole chambers, panels, and other components.

- GRP also offers exceptional thermal insulation and fire resistance.

Uses of GRP

The following are some common applications of GRP across different industries.

- Construction

This sector uses GRP for making roofing sheets, cable trays or ladders, reinforcement bars, manholes and manhole covers, architectural facades, and structural components like beams, panels, and claddings.

- Water and Wastewater Treatment

This industry used GRP for piping, fittings, water tanks, walkways, gratings, handrails, and access covers.

- Transportation and Automotive Industry

In this industry, GRP is used to create vehicle body panels, interior components of buses, front ends, roof panels, and enclosures for electrical control systems.

- Marine Industry

GRP is used in this industry to design boat hulls, decks, buoys, floating structures, and ladders or gratings for offshore platforms.

- Electrical and Telecommunications

GRP’s non-conductive nature makes it ideal for creating cable trays, ducts, support systems, junction boxes, back boxes, poles, masts, and antennae.

- Aerospace and Defense Sector

GRP is used in these industries for making military vehicle components, aircraft interior panels, composite fairings, and radomes.

- Chemical Handling Industries

This sector uses GRP for making process piping, industrial flooring, platforms, storage tanks, scrubbers, and fume hoods.

- Data Centers

This industry utilizes GRP for making flooring for critical equipment, cable management systems, cooling towers, and electrical enclosures.

Conclusion

GRP is an extremely sturdy, versatile, and lightweight material that is the number one choice for most industrial and domestic development projects. This material is durable, cost-effective, low-maintenance, and more functional than concrete, metal, or plastic.

This carefully engineered composite material has all the desirable features of polymer resins and glass fibers combined, which creates a delicate balance between aesthetics, strength, and flexibility.

This innovative material offers sustainable, practical, and affordable solutions for modern development projects, making it a perfect fit for both industrial and residential settings.

You can visit us at Naran Precast Concrete Co. to explore our premium quality GRP products to get maximum durability and better aesthetics in all projects.